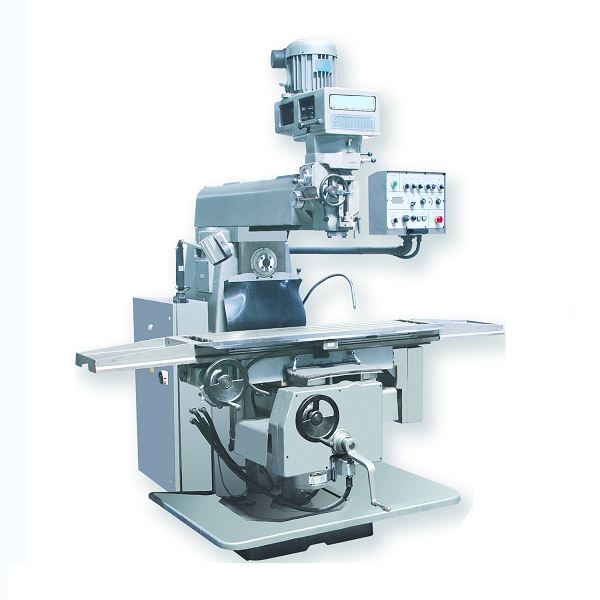

2022 Wholesale Price Cnc Lathe Machine - Precision Metal Turning CNC Lathe Machine Horizontal CNC Lathe CNC6130D Series – Eagle

2022 Wholesale Price Cnc Lathe Machine - Precision Metal Turning CNC Lathe Machine Horizontal CNC Lathe CNC6130D Series – Eagle Detail:

Main Feature And Function

•The bedway、slideway and guideways are hardened and precision ground •Infinitely variable speed for the spindle obtained through inverter motor • Axis X with large stroke• wide bedways • high rigidity and accuracy, run smoothly with low noise • Design of electromechanical integration, easy operation and maintenance• Clamping methods of manual chuck, power chuck and spring collect are interchangeable.

Standard Configuration

Air collet, Air Tail Stock, lighting system, automatic lubricating system, cooling system, GSK980Tb2 CNC system, 4 station electric tool post.

Special Configuration

• gang type tool holder、6 station electric tool post, sleeve spring collet, pneumatic chuck, other brand CNC system.

Specifications

| Model | CNC6130D |

| Item No | 118041 |

| Max. swing dia. over bed | ф340 |

| Max. swing diameter over table | 170mm |

| Spindle speed (infinitely) | 100-4000r/min |

| Spindle bore | 42mm |

| Spindle taper | MT5 |

| Distance between centers | 435mm |

| Max. longitudinal stoke | 435mm |

| Max. cross stoke | 260mm |

| Tailstock stroke | 70mm |

| Tailstock taper | MT3 |

| Turning tool size | 20 x20mm |

| Rapid feed | X:6 Z:8 m/min |

| Circle | 0.005mm/100mm |

| Cylinder | 0.016mm/100 mm |

| Power of motor | 3KW |

| Min. setting unit | 0.001mm |

| Repositioning accuracy | X: 0.012 Z:0.016 mm |

| N.W./G.W. | 1100/1200Kg |

| Overall dimensions(L´H´W) | 1600x1470x1950mm |

| Standard system | Siemens 808D |

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new solutions into the market each year for 2022 Wholesale Price Cnc Lathe Machine - Precision Metal Turning CNC Lathe Machine Horizontal CNC Lathe CNC6130D Series – Eagle , The product will supply to all over the world, such as: Houston, belarus, Adelaide, We have top engineers in these industries and an efficient team in the research. What is more, now we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Remember to find our website to check more information from our merchandise.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!