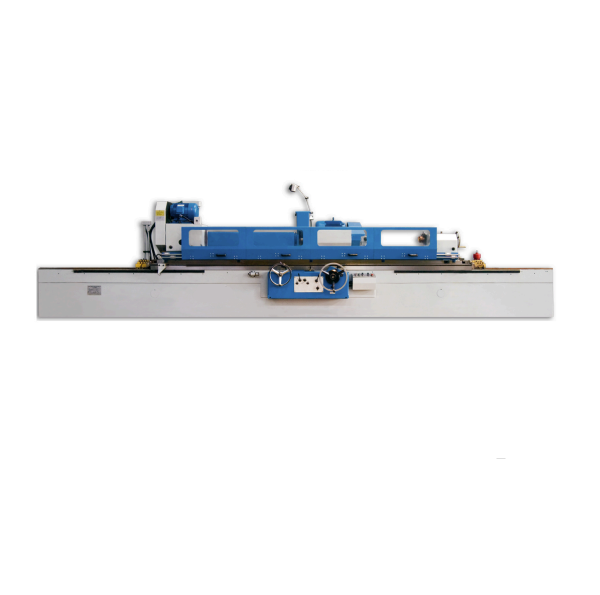

Precision Grinding Purpose Universal Cylindrical Grinding Machine

* Introduction

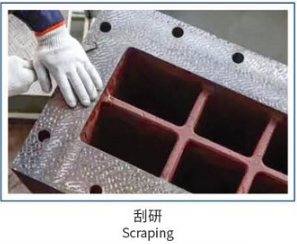

1. The left and right guide rail adopts P-V structure, which is scraped by high precision manual, so that the whole system products have high precision and high stability.

2. The front and rear feed guide rail of grinding wheel can choose roller and wire rail structure.

3. Classic control mechanism, simple, safe and reliable.

4. The worktable and grinding wheel guide rail adopts high stable hydrostatic guide rail, high rigid dynamic and static pressure spindle.

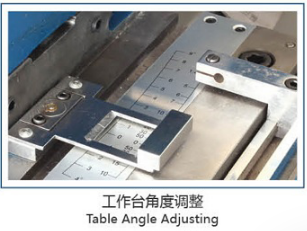

5. Universal workhead can be adjusted at any Angle within 90 degrees counterclockwise to adapt to chuckgrinding internal and external control workpiece.

| Description | Unit |

Specification |

||||||||

| Item NO. | 122015 | 122016 | 122027 | 122028 | 122029 | 122030 | 122031 | 122032 | 122033 | |

| Model | UCG2050 | UCG2075 | UCG32100 | UCG32150 | UCG32200 | UCG32300 | UCG50150 | UCG50200 | UCG50300 | |

| General Capacity |

|

|||||||||

| Max.length ground(O.D) |

mm |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

1500 |

2000 |

3000 |

| Center height |

mm |

135 |

180 |

180 |

270 |

|||||

| Dia. Ground(O.D) |

mm |

8~200 |

8~320 |

8~320 |

25~500 |

|||||

| Dia. Ground(I.D) |

mm |

25~100 |

30~100 |

30~100 |

30-200 |

|||||

| Max.length ground(I.D) |

mm |

125 |

125 |

125 |

320 |

|||||

| Max.weight of work piece |

kg |

100 |

150 |

500 |

1000 |

|||||

| Workhead |

|

|||||||||

| Swiveling angle |

º |

90 |

90 |

90 |

90 |

|||||

| Center taper(MT) |

MT |

4 |

4 |

5 |

6 |

|||||

| Spindle speed/Stepless |

r/min |

50HZ: 26~260 |

50HZ: 26~260 |

50HZ: 26~260 |

50HZ: 20~224 |

|||||

| Wheelhead |

|

|||||||||

| Max dimension of wheel(OD*W*ID) |

mm |

400×50×203 |

400×50×203 |

500×50×203 |

500×75×305 |

|||||

| Wheel peripheral velocity |

m/s |

35 |

35 |

35 |

35 |

|||||

| Hand feed per.rev |

mm |

rough:2 |

rough:2 |

rough:2 |

rough:4 |

|||||

|

mm |

fine:0.5 |

fine:0.5 |

fine:0.5 |

fine:0.5 |

||||||

| Hand feed per.gra |

mm |

rough:0.01 |

rough:0.01 |

rough:0.01 |

rough:0.02 |

|||||

|

mm |

fine:0.0025 |

fine:0.0025 |

fine:0.0025 |

fine:0.0025 |

||||||

| Internal grinding device |

|

|||||||||

| Spindle speed |

r/min |

10000 |

10000 |

10000 |

10000 |

|||||

| Dimension of wheel |

mm |

max:50×25×13 |

max:50×25×13 |

max:50×25×13 |

max:175×32×32 |

|||||

|

mm |

min:17×20×6 |

min:17×20×6 |

min:17×20×6 |

min:30×25×10 |

||||||

| Table |

|

|||||||||

| Max.swiveling angle of Table(Cockwise) |

º |

3º |

3º |

3º |

3º | 2º | 2º | |||

| Max.swiveling angle of Table(Anticlockwise) |

º |

9º | 8º | 7º | 6º | 5º | 3º | 6º | 5º | 3º |

| Longitudinal speed range of table |

m/min |

0.1~4 |

0.1~4 |

0.1~3 |

0.1~3 |

|||||

| Tailstock |

|

|||||||||

| Center taper(MT) |

MT |

4 |

4 |

5º |

6 |

|||||

| Quill travel |

mm |

30 |

30 |

30 |

70 |

|||||

| Motor |

|

|||||||||

| Wheelhead motor power |

Kw |

4 |

5.5 |

7.5 |

5/7.5 |

|||||

| Internal grinding |

Kw |

1.1 |

1.1 |

1.1 |

1.5 |

|||||

| Workhead motor power |

Kw |

1.1 |

1.5 |

1.5 |

4 |

|||||

| Machining accuracy |

|

|||||||||

| Roundness |

μm |

2 |

2.5 |

3 |

2.5 | 3 | 3 | |||

| Cylindricity |

μm |

5 |

8 |

8 |

8 |

8 | 8 | 8 | ||

| Roughness |

μm |

Ra0.2 |

Ra0.2 |

Ra0.32 |

Ra0.32 |

|||||

| Machine |

|

|||||||||

| Gross weight |

kg |

4100 |

4300 |

4600 |

5100 |

6200 |

7600 |

10000 |

11000 |

13000 |

| Packing dimension |

cm |

235*203*205 |

275*203*205 |

326*190*205 |

426*190*205 |

580*190*205 |

780*190*205 |

543*225*210 |

583*225*210 |

796*225*210 |

| Description | Unit |

Specification |

||||||||||||

| Item NO. | 122103 | 122104 | 122105 | 122106 | 122111 | 122112 | 122113 | 122121 | 122122 | 122123 | 122131 | 122132 | 122133 | |

| Model | CGM32100 | CGM32150 | CGM32200 | CGM32300 | CGM50150 | CGM50200 | CGM50300 | CGM63300 | CGM63400 | CGM63500 | CGM80300 | CGM80400 | CGM80500 | |

| General Capacity | ||||||||||||||

| Max.length ground(O.D) |

mm |

1000 |

1500 |

2000 |

3000 |

1500 |

2000 |

3000 |

3000 |

4000 |

5000 |

3000 |

4000 |

5000 |

| Center height |

mm |

180 |

180 |

270 |

370 |

500 |

||||||||

| Dia. Ground(O.D) |

mm |

8~320 |

8~320 |

25~500 |

30~630 |

50~800 |

||||||||

| Max.weight of work piece |

kg |

150 |

500 |

2000 |

3000 |

3000 |

||||||||

| Workhead |

|

|||||||||||||

| Center taper(MT) |

MT |

5 |

5 |

6 |

Metric 80# |

Metric 80# |

||||||||

| Spindle speed/Stepless |

r/min |

50HZ: 19~190 |

50HZ: 10~100 |

50HZ: 10~100 |

50HZ: 6~60 |

50HZ: 5~50 |

||||||||

| Wheelhead |

|

|||||||||||||

| Max dimension of wheel(OD*W*ID) |

mm |

600×75×305 |

600×75×305 |

750×75×305 |

750×75×305 |

900×75×305 |

||||||||

| Wheel peripheral velocity |

m/s |

35 |

35 |

35 |

35 |

35 |

||||||||

| Hand feed per.rev |

mm |

rough:2 |

rough:2 |

rough:4 |

rough:4 |

rough:4 |

||||||||

|

mm |

fine:0.5 |

fine:0.5 |

fine:0.5 |

fine:0.5 |

fine:0.5 |

|||||||||

| Hand feed per.gra |

mm |

rough:0.01 |

rough:0.01 |

rough:0.02 |

rough:0.02 |

rough:0.02 |

||||||||

|

mm |

fine:0.0025 |

fine:0.0025 |

fine:0.0025 |

fine:0.0025 |

fine:0.0025 |

|||||||||

| Table |

|

|||||||||||||

| Max.swiveling angle of Table(Cockwise) |

º |

3º |

3º |

3º | 2º | 2º |

1º |

1º |

||||||

| Max.swiveling angle of Table(Anticlockwise) |

º |

7º | 6º | 5º | 3º | 6º | 5º | 3º | 3º | 2º | 1.5º | 3º | 2º | 1.5º |

| Longitudinal speed range of table |

m/min |

0.1~4 |

0.1~3 |

0.1~3 |

0.1~2.5 |

0.1~2.5 |

||||||||

| Tailstock |

|

|||||||||||||

| Center taper(MT) |

MT |

4 |

5 |

6 |

Metric 80# |

Metric 80# |

||||||||

| Quill travel |

mm |

30 |

30 |

70 |

70 |

70 |

||||||||

| Motor |

|

|||||||||||||

| Wheelhead motor power |

Kw |

11 |

11 |

15 |

22 |

22 |

||||||||

| Workhead motor power |

Kw |

1.5 |

3 |

4 |

15 |

15 |

||||||||

| Machining accuracy |

|

|||||||||||||

| Roundness |

μm |

2.5 |

3 |

2.5 | 3 | 3 |

3 |

3 |

||||||

| Cylindricity |

μm |

8 |

8 |

8 | 8 | 8 | 8 | 12 | 12 | 8 | 12 | 12 | ||

| Roughness |

μm |

Ra0.2 |

Ra0.32 |

Ra0.32 |

Ra0.32 |

Ra0.32 |

||||||||

| Machine |

|

|||||||||||||

| Gross weight |

kg |

4600 |

5100 |

6200 |

7600 |

10000 |

11000 |

13000 |

22000 |

23000 |

26000 |

22000 |

23000 |

26000 |

| Packing dimension |

cm |

326*190*205 |

426*190*205 |

580*190*205 |

780*190*205 |

543*225*210 |

583*225*210 |

796*225*210 |

876*240*226 |

1100*240*226 |

1270*240*226 |

876*240*230 |

1100*240*230 |

1270*240*230 |

| Optional Accessories |

| Grinding wheel balancing frame |

| Magnetic separation |

| Paper bag filter |

| Grinding Center device |

| Close Center frame |

| Device End dresser |

| Device circular dresser |

| Standard Accessories |

| Cooling water tank |

| External circle dresser |

| Grinding wheel chuck and handling tools |

| Standard grinding wheel |

| Balance shaft |

| Leveling pad iron |

| Working light |

| Open center frame |

| Center |

| Internal round abrasives |